Whatever the trouble, there’s no better excuse for poor performance than the system, right? At mid-size manufacturing companies, we are incredibly dependent on our ERP systems. Demand forecasts, material requirements planning, shop floor scheduling and more. That dependency isn’t always healthy. Sometimes it’s downright pathological.

And when performance turns poor, that dependency often turns into blame. Repeated blame starts to slowly morph into a standard excuse for problems of all kinds. Repetition of the excuse cements it in people’s minds as a fact. So, when problems arrive, and they always do, it’s no wonder the finger of blame is quickly pointed at the system. It’s the ERP Blame Game.

Pretty soon those problems that are supposedly the system’s fault are just accepted as something we can’t do anything about. Kind of like bad weather.

So, when problems arrive, and they always do, it’s no wonder the finger of blame is quickly pointed at the system. It’s the ERP Blame Game.

So what exactly is the truth? Is it our ERP system’s fault, or is it us?

In this article, The Industrial CFO explores the ERP systems blame game that many companies find themselves in. We’ll look at how this happens at otherwise healthy companies, and what you can do to manage your way out of this situation.

First Impressions

We were all taught early in life that first impressions count the most. Ask yourself, what was your first impression of the ERP system that is in place at your company? How was it described to you? Now think of your new hires. What are the first impressions your new hires receive of your ERP system? How is the system introduced to new users?

We would hope that the conversation goes something like, “And here we have our Acme ERP system. It is simply amazing. It makes our lives so much easier. It is so easy to use, and it rarely ever has a problem. We drop orders into the system, and it takes care of everything from there. It always works as expected and it is easy to maintain, even for non-experts.”

If that is how things go for you at your company, congratulations! If the typical ERP experience at your company is not quite so positive, I hope we can help.

Send Me Future Posts & Articles

How are folks introduced to your ERP system? Is your organization regularly sowing seeds of distrust right from Day One?

Impression Setting

From my experience, and from some very informal surveying of folks in the mid-sized manufacturing space, most introductions to a company’s ERP system do not happen the way I described above. I have observed that there are three common types of introductions to ERP systems that happen in real-life, as follows.

Don’t Blame Me, I Just Work Here

This introduction is from the Sergeant Schultz playbook from Hogan’s Heroes (sorry young ones). It means, “I am not going to say anything good, or anything bad. Maybe there’s some bad stuff associated with this thing, but I don’t know anything about it.”

In business terms this includes statements that make it clear that this system wasn’t your idea, that you’re not vouching for the system, and that if it causes you problems, my dear new hire, don’t blame me. That really inspires incredible confidence in a new hire, right? And really re-enforces the importance of the system to the company’s success. (That’s sarcasm.)

It’s Very Complicated; We’ll Teach That to You Later

This is a classic move that should make every procrastinator proud. This means just what it says. The company views the system as difficult to work with. And they’re not looking forward to training you on it.

It tells the new hire (1) you have a system that is going to be difficult to learn, (2) that learning it is not something that should start today (for some reason!), and (3) it creates a giant mountain on the horizon that your new hire knows is there, but can’t get to.

The System Has Some Problems, but We Work Around Them

This is better than the previous two in some obvious ways. But it is also kind of worse in some sneaky ways. This version of the ERP system rings true for many companies. It means, “We use this system in a certain way that we have evolved to over the years. It’s probably not right. And we know that. But it seems to be the best we could do, so we live with it.”

The biggest problem here is that it conveys the idea that this less-than-great system setup is the final stage, and whatever is not so good, well, you’ll just have to live with it and figure out how to deal. This is very problematic. We’ll talk about that.

Frustration with the ERP system is a leading cause of poor performance… and, well, frustration.

The Truth Hurts

I have talked about this topic with folks for years and one of the common replies goes along the lines of, “Well, the truth hurts, our system does give us a lot of problems.” Crazier still is that this is often said, even by pretty smart folks, as if the ERP system was an independent player of some sort, with a mind of its own.

The ERP Blame Game is typically enabled by a good dose of denial.

The reality is that the ERP system is something that we ourselves created. We own it, we drive it, we maintain, and we can kill it, anytime we want. That’s the truth.

The follow on to that first truth is that we have the power to change our lousy, dis-empowering systems narrative anytime we want.

The reality is that the ERP system is something that we ourselves created. We own it, we drive it, we maintain, and we can kill it, anytime we want. That’s the truth.

Changing the Blame Game Narrative

The best way to change the negative narrative on your systems, and the defeatist attitudes that naturally come along with it, is to take ownership of the issue. Funny how “taking ownership” is the answer to so many of life’s problems, especially those “caused” by other things and people.

Fortunately, in this case, taking ownership is easy. Because you already have ownership. You just haven’t realized it, or like Sergeant Shultz, you’ve denied it. Now it is time to grab the steering wheel on your company’s systems future by acting in the present.

Change the narrative around your company’s ERP System by taking the wheel and charting your own destiny!

What’s the Plan, Stan

It always starts with a plan. In this case, it’s simple. What do you want your ERP system to do, and how are you going to make it happen? Sounds daunting perhaps, but it’s not. Why? Because any plan that you actually commit to and follow is likely better than what you’re doing today.

I don’t mean bad or stupid plans, obviously. They will take you backwards. But if you’re just getting started, it’s okay to take a 30,000 foot view at first. Try it. In plain English. What do you want your ERP system to do, and how are you going to make it happen?

I’ve Got a Bad Answer For You

I had a great boss who was a highly accomplished executive and a leading expert in motivating leaders to achieve peak performance. He was the best I’ve ever seen at starting tough conversations. He used a trick where he threw out what he called ‘bad answers’. They were never bad answers at all of course, but it was a clever, light-footed way to get difficult conversations started.

In that spirit, I’ll give you a bad answer as to those questions about your ERP system. First, remember, when we give an answer like this at The Industrial CFO, we are generally speaking most directly to small to mid-sized manufacturing companies. For other folks in other niches, I think you’ll find these principles are solid, though some of the nuances may be different.

If you’re a small to middle market manufacturing company that is just getting serious about your systems, you may consider the following as your answers.

From the Mountain Top

Here’s a vision from way up high. I don’t know your particular company obviously, so I am speaking in generalities here.

-

- You want your ERP system to do basic transaction flows in a near-flawless manner.

- You want the data required for those processes to be very accurate.

- You want to commit to adding greater functionality, as you attain mastery of the basics.

- You are serious, so you’re willing to track and report on how you’re doing, not just ‘try harder’

If you’re just starting to focus on optimizing your ERP system, this is where to start.

ERP systems can do absolutely amazing things. The ERP company’s sales teams will sell you on the sizzle, but you need to be concerned about the steak. Fancy bells and whistles are not going to ensure on-time deliveries.

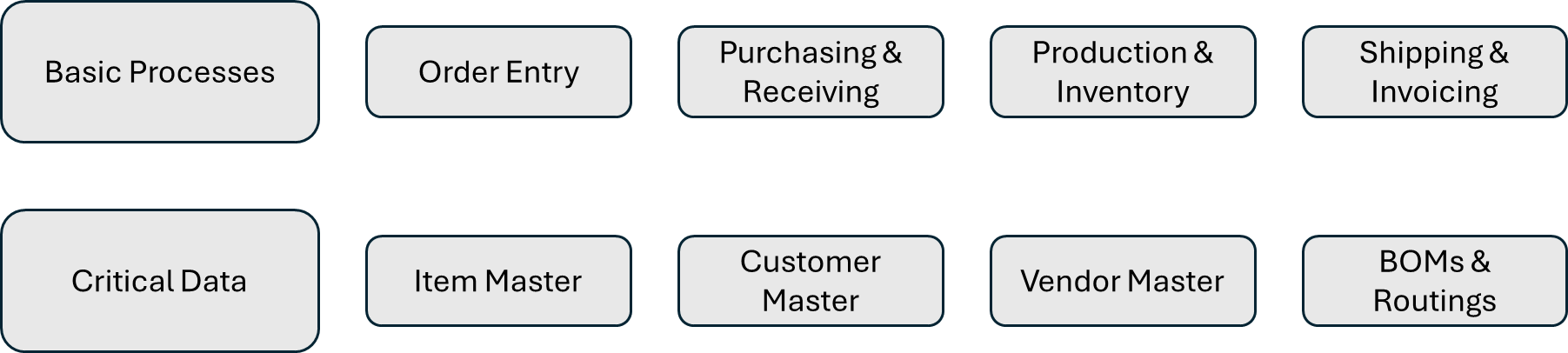

Which Processes Matter Most

Simply said, you want flawless system behavior for your most important operations workstreams. The primary workstreams that most small to mid-sized manufacturing companies need to worry about are as follows.

-

- Order Entry

- Purchasing & Receiving

- Production & Inventory

- Shipping & Invoicing

I know there are additional important processes, obviously. But at most small to mid-sized companies, these four are your bread and butter, life and death processes. And when I say we want flawless behavior, that does NOT mean that the system does fancy tricks. To me, flawless simply means that those basic processes consistently operate the way you intend them to operate, and they don’t cause downstream problems for any other processes.

If these basic processes are not working really, really well, forget the whole thing. Seriously. Stop. Do not pass go. Get this basic stuff right or you will fail.

Data, Data, Data

The processes above are just that, processes. They manipulate data to conduct business transactions and activities along a series of workstreams. Without data, they are like a network of highways with no cars. The data entered in the system are the cars that travel along these workstream highways. Together, the two enable what we perceive as the forward movement of business processes.

In the same way that we recognize critical basic processes, we can recognize critical data. The two are closely related. In fact, I would define critical data as that data which is needed to support the smooth consistent operation of your basic processes.

Accurate data is needed for your system to perform successfully. Accuracy of basic data is absolutely critical!

Which Data Matters Most

For most small to mid-sized manufacturing companies, the most critical data sets are as follows.

-

- Item Master

- Customer Master

- Vendor Master

- Bills of Materials and Routings

Data masters are another area where there are many, many fields. There can be hundreds of fields for a single data master, which can make gaining control of them feel impossible.

While it would be great to explore all of our data master fields and optimize their use, in the early days of gaining system control, you should simply shut down as many fields as you can.

Again, my test would be to ask if each field is required to support the basic processes you are optimizing.

What Matters Most

Other Pieces

Every ERP system has an accounting component as well. The correct design of your accounting component is critical to your success. I have left that out of this discussion as it is a whole other animal to discuss another day.

Operationally, there are obviously other parts of the company that draw and provide support from and to the ERP system like Quality, Engineering, HR, and others. Newer systems have Business Analytics and other functionality built in too. The features are awesome.

You should have those too in the future, but if you want them to actually work, you need to get your foundation right starting today.

Pretty Good Ain’t Good Enough For These

Note that I stressed that you need to have a high level of understanding of your basic processes and data. I stress that because a lot of folks think their basic systems work well. It’s funny. Everyone thinks that their basic processes are all good. They tell us all the time that’s its only their higher-level functionality that flops. That they’ve got the basics covered.

The fact is the higher-level functionality usually fails because the basic processes are NOT right.

Know this. Just because something appears to the eye to be working fine, that doesn’t mean that is so. The car is such a great metaphor for so many things. We all know that old Betsy may be chugging along just fine, while at the same time problems may be brewing under the hood, tucked out of sight. She may make it to the store just fine, but if you try to push her, you may be in for a world of hurt. This is the same thing.

If you’re serious about growing your business, you better have your machine- your basic processes- working exactly the way they were designed.

Would you be confident setting out on a trip with your family in a car without a dashboard? Business Analytics can ensure we know the true health of our business.

Under the Hood

Those basic ERP processes may appear to work just fine on the surface. Take order entry. We enter the orders, and then we ship them, that’s easy. But the order process has a bunch of wrinkles that you don’t know about. The average set of fields for order entry in an ERP system is north of 100 fields.

Isn’t that wonderful? Your system can do so many things that it takes a hundred fields to do it all. So that’s 100 chances for your wage-challenged customer service folks to screw something up on every order your team enters. And if there are systematic errors, they are likely to be baked into every order you enter.

And you’ll never know any of this by looking at the orders. When you look at them, each one looks right. What you don’t know is that there is that series of fields on that section on the third tab of the order entry screen that has a bunch of settings. And some of those settings may be set very badly for your business model.

Ask your team when the last time they have done a serious review of your systems field settings. The answer may scare the hell out of you.

Nobody said tackling the ERP Blame Game was for the weak of heart.

Silent but Powerful

Field settings are one of the most powerful, yet silent, features of an ERP system. Imagine a company that has a field setting directing the system to purchase items in lots of 100. Then imagine discovering that because of poor basic processes, the field setting on that item was copied to the next 100 items created. You would likely purchase significant quantities of unwanted inventory before the problem revealed itself.

I have seen multiple small to mid-sized manufacturing companies with millions of dollars in excess inventory as a direct result of some version of what I described above. Remember the order entry screens, the ones that had over 100 fields? The Item Master makes that seem simple. It can have 200 or more; many informational, many operational. Do you know which is which?

To really understand your processes, you’ve got to get under the hood.

ERP Field Settings… Quiet & Powerful… and Potentially Deadly.

Back to the Mountain Top

So, pulling ourselves back to our mountaintop view. We have a new vision. We are going to focus on gaining mastery of our basic processes and the critical data that supports them. We are going to take an inventory of what we know and what we don’t, what we have and what we need, and then develop an action plan to gain that mastery. Value stream mapping is an excellent methodology to acquire that mastery. We’ll cover those in future posts. Your transformation will not happen overnight. Depending on where you are at, it may take six months. It may take two years. But it’s a plan and its meant to be achieved.

At the end of that period, or at the appropriate time, we will add additional features. Everything we do will be in concert with an overall plan that is understood by all. When we add additional features, they will work. This is no small thing. Again, most companies think that when the advanced features of an ERP system are not working, it’s because the advanced features are broken. Usually not. They don’t work most often because their basic processes and the data those processes depend on are broken.

A New Narrative

Armed with an understanding of how to finally obtain control over our ERP destiny, we are now able to re-write that ERP narrative that has been self-defeating for so long. Instead of ERP being the stepchild that nobody wants to take responsibility for, imagine thinking of your ERP system as a competitive advantage! Imagine feeling confident that you are doing ERP right, while most folks are not.

Obviously, the replacement of a corporate legend does not happen with the press of a button. You have to sell it, baby. But that really shouldn’t be too hard. After all, hasn’t everybody been griping about the system anyway? Won’t everyone be happy to hear you’re going to fix it?

You are in good company here. Leading studies from experts at Gartner Group and Forrester Wave regularly note general user dissatisfaction with legacy ERP systems, including difficulties with integration, outdated technology, and limited functionality, all of which contribute to a push towards modern ERP solutions.

Your biggest battle will be credibility. Especially true if you have been down this road before and didn’t get it done. Don’t worry about it. That’s happened to companies better than yours. Suck it up now and get it done.

Get your LT together, commit to a plan and do it. Take whatever time you need, but keep the ball moving forward. Tell folks what you are doing. Tell everybody. Make it a focus. Write about it in your newsletter. Give it a name. Appoint a project leader. Keep painting the picture of the better tomorrow.

Companies are changing their ERP Narrative from Losing to Winning! Is your company still stuck playing the ERP Blame Game? Change that today!

This point is real important. Involve people in the effort. They know the system. Ask them for their help. You need it. Thank them publicly for major contributions. Do not stop until your entire company is convinced of the commitment to an awesome system. Flip the script for management from threats about ignoring the system to praise for contributions to our new system, the one that gives us a competitive advantage. Keep it real. With Leadership truly on board and committed, the troops will follow.

We can now empower new folks on day one with a new introduction to our ERP system that is powerful and motivating. We can describe our company as one that is at the leading edge of developing and utilizing technology for small to mid-size manufacturing companies. We can enlist their help and involvement from day one to the continuous improvement of our system. Best of all, we can walk the halls with the confidence of winners, and we can say goodbye once and for all to the ERP Blame Game!

THE END

Great summarization of “what happens”, and outline for what can happen. Thank you!

Thank you for the comment! As an expert and leader in the field, your feedback means a lot to us!

Great information!

Thank you Grace! Really appreciate the feedback!